Home / Polymer Extrusion Components & Gearbox Repair | Zala Machine Co.

Zala Machine Co. is a premier partner for the plastic polymer extrusion industry, specializing in the manufacturing and modification of mission-critical production hardware. Operating out of our high-capacity machine shop in Hillsborough, NJ, we combine 5-axis CNC technology with deep industry expertise to reduce your downtime and optimize your melt quality.

The performance of a blown film line depends on the mathematical precision of the die internals. We leverage our Mori Seiki NTX2000 5-axis mill-turn center to produce complex die geometries that ensure uniform gauge control.

5-Axis Spiral Die Machining: We specialize in machining complex spiral mandrels and distribution plates, ensuring perfectly smooth flow paths to eliminate gauge variation and weld lines.

Co-Extrusion Complexity: Our capabilities extend to multi-layer feed blocks and die heads requiring intricate internal porting and extreme surface integrity.

Optical Surface Finishes: We achieve the ultra-smooth internal finishes necessary for high-clarity films, preventing material stagnation and carbonized defects.

Engineering Tolerance: Every die component is verified for concentricity and parallelism to maintain a consistent melt curtain.

Whether your line requires square, rectangular, or round geometry, Zala manufactures feed components designed for maximum laminar flow and durability.

Monolithic Construction: We specialize in machining extended elbows and feed sections from one solid piece of material, eliminating the welds and stress points found in standard assemblies.

Laminar Flow Optimization: Regardless of the exterior shape, internal flow paths are precision-contoured and polished to a 4–8 RMS mirror finish to prevent material hang-up and degradation.

Versatile Geometry: Our shop produces custom short-radius elbows, rectangular transition blocks, and extended tube sections tailored to your specific machine footprint.

Superior Durability: Machined from high-grade tool steels and corrosion-resistant alloys, our pipes and elbows are built to withstand high-pressure and abrasive resin environments.

Our breaker plates are designed to survive the most abrasive resins while providing optimal filtration support.

High-Density Perforation: Advanced CNC drilling allows for maximum hole density to increase throughput without compromising the structural integrity of the plate.

Wear-Resistant Materials: We machine plates from 4140HT/4340HT, 15-5Ph, 17-4Ph, H13, D2, and 420 Stainless Steel, heat-treated to resist erosion and pressure-induced deflection.

Precision Sealing Surfaces: Surface grinding ensures perfectly flat and parallel mating surfaces, providing a gas-tight seal that eliminates material leaks at the head.

When your drive system fails, OEM lead times can stall your entire production schedule. Zala Machine Co. offers a total recovery solution for extruder gearboxes that eliminates the wait.

Full-Spectrum Overhaul: Complete disassembly, failure analysis, and replacement of all bearings and seals to restore OEM performance.

In-House Gear Cutting: We manufacture new gear blanks and cut replacement gears from high-strength 4140/4340 alloys when original parts are unavailable.

Housing & Bore Restoration: We utilize large-scale CNC boring mills to repair cracked housings and sleeve bearing bores, ensuring perfect shaft alignment.

Emergency Turnaround: Local NJ facility provides faster response times than international OEMs for critical gearbox failures.

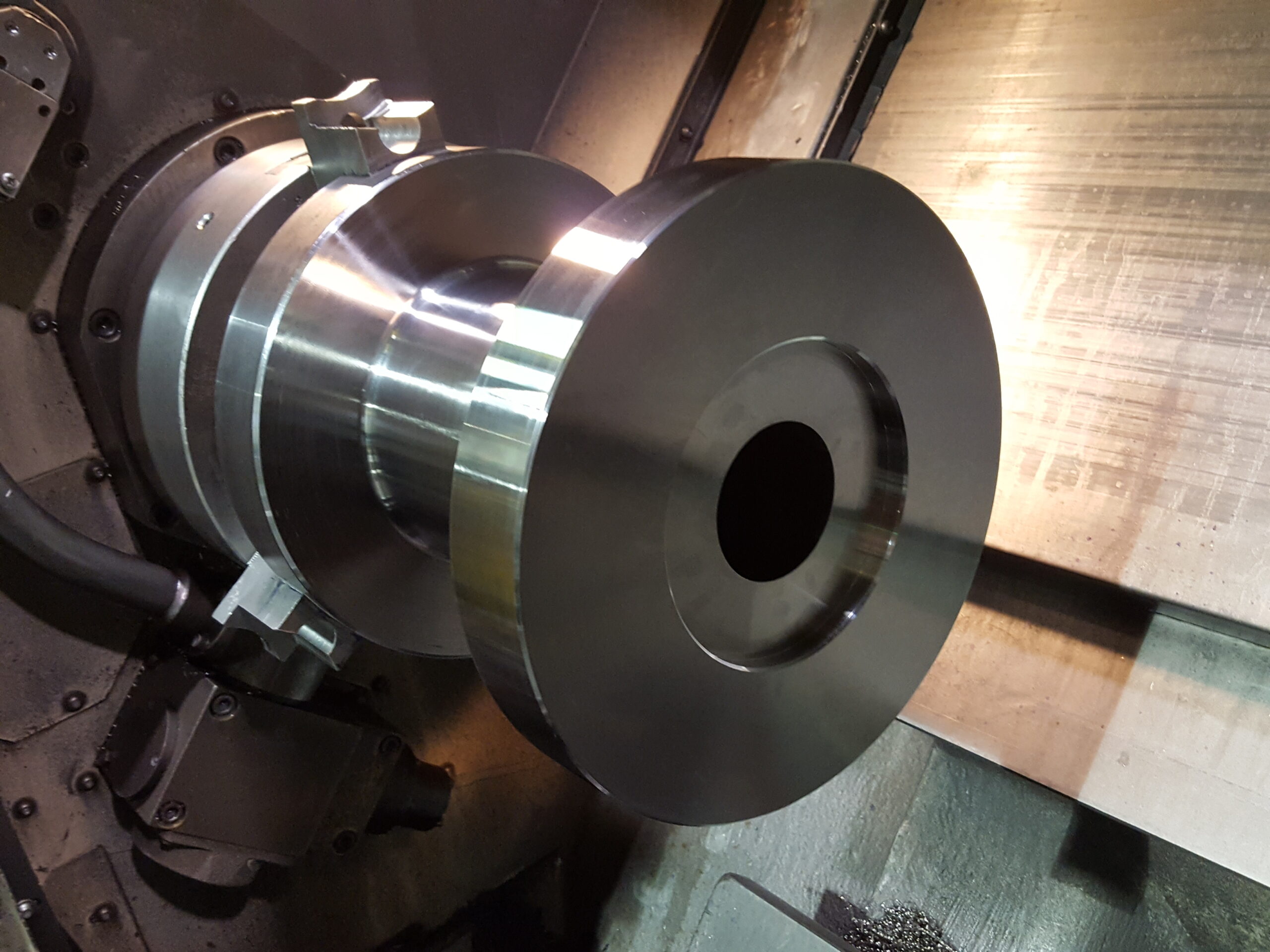

A worn barrel leads to inconsistent compression and material surge. We provide the technical modifications required to restore or upgrade your barrel’s performance.

ID Restoration: Precision internal boring and honing to remove wear patterns and restore a mirror finish across the entire length of the barrel.

Gundrilled Cooling Channels: We utilize specialized deep-hole gundrilling to add or modify thermal management channels within the barrel wall.

Liner Prep & Support: We machine barrels to the exact interference fit required for the installation of bimetallic liners, preventing polymer seepage.

The integrity of your extrusion line starts at the drive connection. We ensure that your torque is delivered without the vibration that destroys thrust bearings.

Extreme Concentricity: We machine adapters to tolerances of +/- 0.001” to guarantee perfect alignment between the gearbox and the screw.

Custom Interface Engineering: We specialize in custom-machined adapters that allow you to retrofit modern, high-torque gearboxes onto existing extruder frames.

High-Load Metallurgy: Components are machined from heat-treated tool steels designed to withstand the massive axial pressures of high-output extrusion.

Advanced 5-Axis Milling: Necessary for the complex geometries found in modern spiral blown film dies.

Material Diversity: Experts in machining P20, H13, 400-series Stainless, and high-nickel superalloys.

Hillsborough, NJ Shop: Strategic support for manufacturers across the East Coast with faster turnarounds than overseas suppliers.

With 5-axis machining, we can tackle even the most challenging projects, delivering parts that previously seemed unattainable. Our skilled team of engineers and machinists harnesses the full potential of this technology to bring your visions to life.

Up to 24″ Diameter Turning x 60″ Long

Blown Film Die/Aerospace/Energy

Our advanced CNC machining centers and an experienced team of engineers guarantee excellent results. Regardless of the complexity of the project or specification, we are ready to meet your requirements. Our machines are equipped with the latest technology.